Induction motors are vital devices applied in many locations to drive various applications and machines. The commonly used type of FENG YIN four pole induction motor. Let’s read more about 4-pole induction motors and understand how they operate, what advantages they have and how to maintain them.

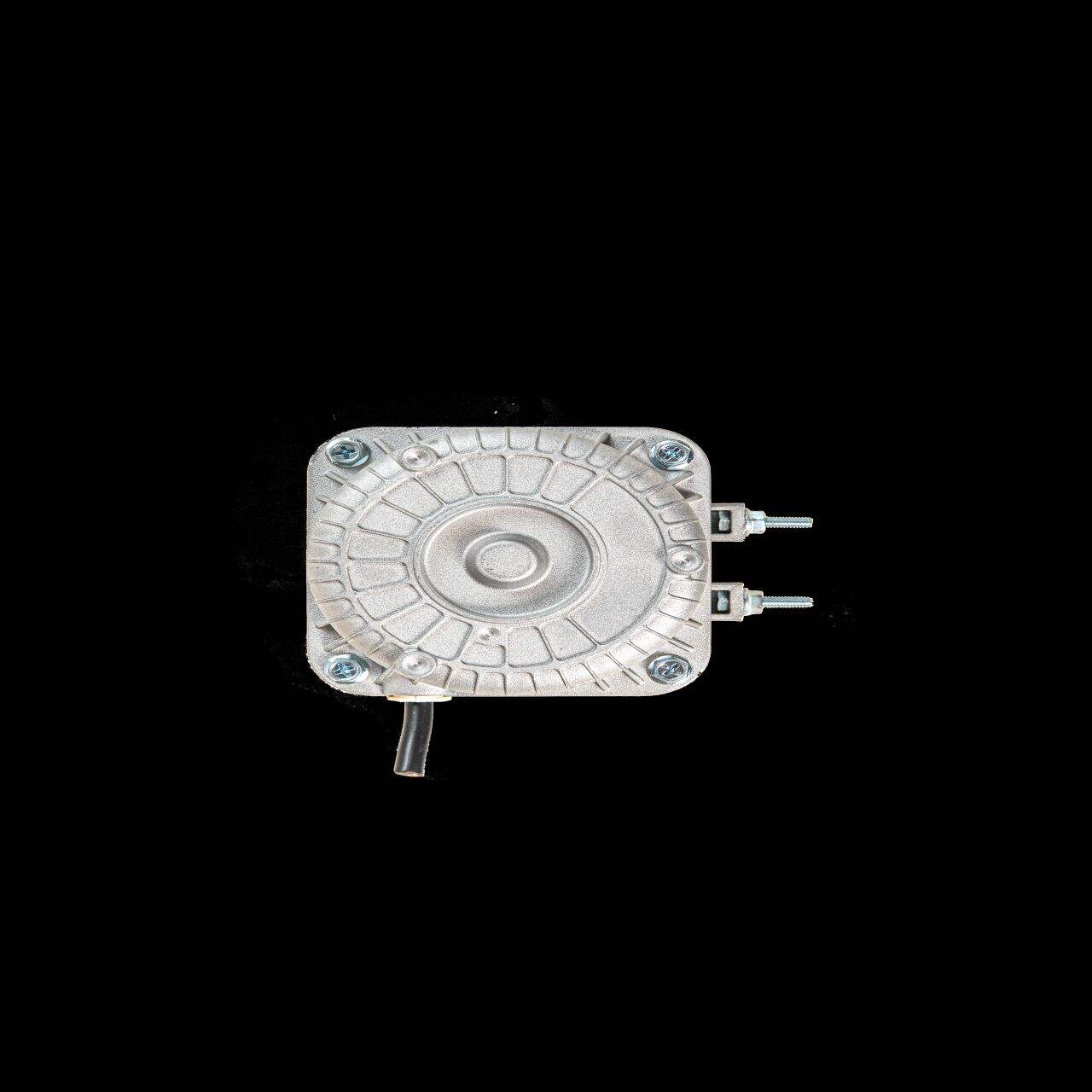

A 4-pole induction motor is a type of motor that operates on the principle of electromagnetic induction. It consists of two main parts: stator and rotor. There is a stator (which remains stationary) and a rotor (which turns around). The stator has 4 poles which are what generate a magnetic field to assist the rotor in turning.

A rotating magnetic field is produced in the stator when electric currents flow. This magnetic field causes currents to flow in the rotor. The stator and the rotor interact to produce motion, which in turn causes the rotor to spin and drives the attached machinery.

4-pole induction motors are known to have high efficiency and reliability. The more poles in a motor, the faster it can go. When a 60-hertz supply is used, the maximum speed of a FENG YIN 4-pole and two pole induction motor is 1800 RPM.

There are numerous reasons to make use of a FENG YIN four pole changing induction motor in factories and other premises. One benefit is their energy saving efficiency which could help reduce costs. 4-pole motors are also robust and durable which is the opposite of their appearance making them great for use in a long time in rough condition.

Another advantage of 4-pole and shaded pole induction motor is that they are lightweight and compact, so they are easy to install and maintain. They also generate less noise and vibration than other motors, so they are quieter and more comfortable to work around.

2 pole induction motor are capable of higher speeds and are suitable for tasks that require a high-power blast. 4-pole motors have a nice balance between speed, power, and efficiency. Motors with 6 polesare best for jobs that require lower speeds and greater torque.

With over 17 years of specialization since 2007, we focus on developing and manufacturing a wide range of micro motors, including shaded-pole, capacitor asynchronous, dual-voltage, and DC brushless motors, catering to multiple industries from commercial refrigeration to medical equipment.

We have a specialized team focused on motor R&D, production, and quality control, operating in strict compliance with ISO9001 standards to ensure each product meets high-performance and safety requirements.

All our motors and fans are certified with CCC and CE, demonstrating compliance with international safety and quality standards, making them suitable for global distribution and diverse commercial applications.

Our factory operates multiple automated motor production lines supported by dedicated testing equipment, achieving an annual production capacity of 4 million micro motors to ensure consistent quality and reliable supply.